DPF Cleaning Machine

The FFSolution FH machine effectively cleans any make and configuration of diesel particulate filter without cutting, modifying or welding the DPF, it does this by simply connecting the appropriate adapter.

INTRODUCING FH DPF CLEANING MACHINE

The FH DPF Cleaning Machine this will successfully clean all types of particulate filters, not just cars, but vans, light, medium and heavy trucks, buses, and any off road equipment that has a diesel particulate filter. It will efficiently remove the PM-10 (Soot & Ash) from the filter restoring the DPF back to 98% original.

There are many different types of diesel particulate filters, most of the ones on cars, light and medium sized trucks are sealed so can be difficult to clean.

The FFSolution FH machine effectively cleans any make and configuration of diesel particulate filter without cutting, modifying or welding the DPF, it does this by simply connecting the appropriate adapter.

After testing the flow rate within the DPF filter the FH machine pumps high pressure water mixed with Hydro Carbon fluid at a rate of 160 litres a minute from a dedicated pump, this cleaning process is assisted with blasts of air at 4bar to ensure the Soot and Ash are completely removed from the DPF filter. To ensure the DPF filter is completely clean the filter is turned both ways.

There are many different types of diesel particulate filters, most of the ones on cars, light and medium sized trucks are sealed so can be difficult to clean.

The FFSolution FH machine effectively cleans any make and configuration of diesel particulate filter without cutting, modifying or welding the DPF, it does this by simply connecting the appropriate adapter.

After testing the flow rate within the DPF filter the FH machine pumps high pressure water mixed with Hydro Carbon fluid at a rate of 160 litres a minute from a dedicated pump, this cleaning process is assisted with blasts of air at 4bar to ensure the Soot and Ash are completely removed from the DPF filter. To ensure the DPF filter is completely clean the filter is turned both ways.

WHAT DO YOU GET?

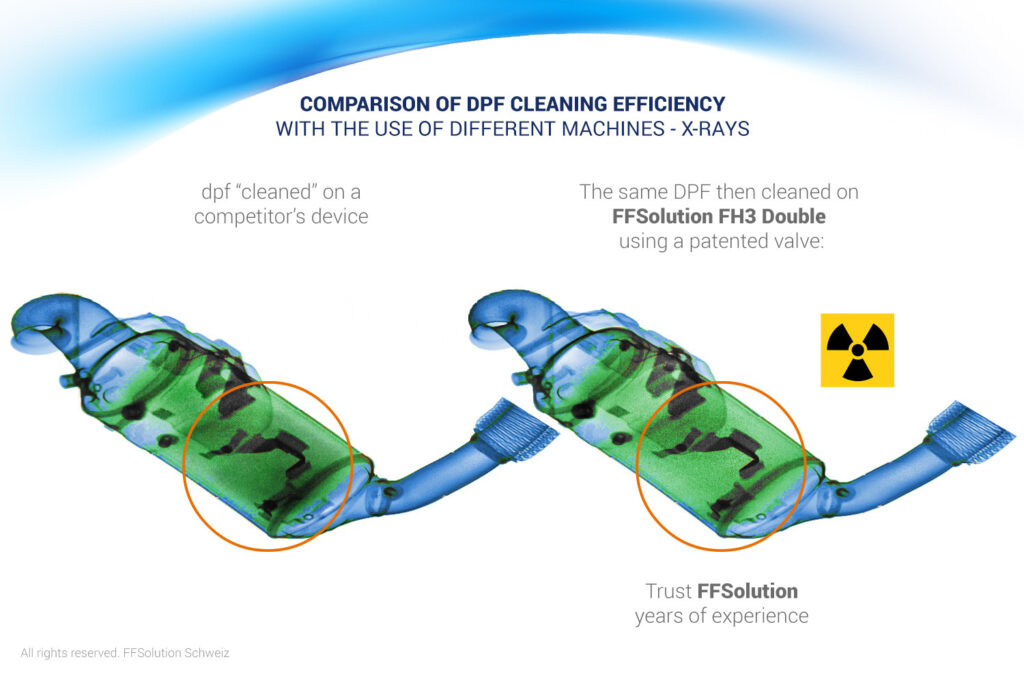

DPF MACHINE COMPARISON

FH DPF CLEANING SYSTEM

The FH DPF cleaning System is revolutionizing the DPF cleaning industry.

An innovative, compact design cleans all particulate filter types for cars, light, medium and heavy trucks, buses, stationary power plants and off road equipment equipped with a diesel particulate filter. It efficiently removes virtually all PM-10 (soot & sulphated ash) from the channels of the filter restoring the DPF to serviceable conditions.

Most DPF cleaning Systems are designed to clean modular canister style filters found on heavy trucks that when the DPF is removed, the full inlet and outlet surfaces of the filter are easily accessible. Many diesel particulate filter designs such as those on cars, light and medium sized trucks have the DOC and DPF housed in a sealed housing in conjunction with small diameter exhaust tubing preventing access to the inlet or outlet surfaces of the filter making it make it difficult or impossible to clean. In these instances the DPF must be cut open, cleaned and welded back together again to restore the filter to serviceable standards or simply replace the DPF costing thousands of dollars.

The FH effectively cleans any make and configuration of diesel particulate filter without cutting, modifying or welding by simply connecting the appropriate fitting.

The FH process outperforms conventional DPF Cleaning technology both economically and in cleaning efficiency because the FH does not utilize pneumatic and/or thermal regeneration technology to remove soot and ash.

There is no need for large volume air compressors, air dryers and expensive electrical service upgrades and the entire

FH System occupies only a fraction of the floor space when compared to other technologies.

An innovative, compact design cleans all particulate filter types for cars, light, medium and heavy trucks, buses, stationary power plants and off road equipment equipped with a diesel particulate filter. It efficiently removes virtually all PM-10 (soot & sulphated ash) from the channels of the filter restoring the DPF to serviceable conditions.

Most DPF cleaning Systems are designed to clean modular canister style filters found on heavy trucks that when the DPF is removed, the full inlet and outlet surfaces of the filter are easily accessible. Many diesel particulate filter designs such as those on cars, light and medium sized trucks have the DOC and DPF housed in a sealed housing in conjunction with small diameter exhaust tubing preventing access to the inlet or outlet surfaces of the filter making it make it difficult or impossible to clean. In these instances the DPF must be cut open, cleaned and welded back together again to restore the filter to serviceable standards or simply replace the DPF costing thousands of dollars.

The FH effectively cleans any make and configuration of diesel particulate filter without cutting, modifying or welding by simply connecting the appropriate fitting.

The FH process outperforms conventional DPF Cleaning technology both economically and in cleaning efficiency because the FH does not utilize pneumatic and/or thermal regeneration technology to remove soot and ash.

There is no need for large volume air compressors, air dryers and expensive electrical service upgrades and the entire

FH System occupies only a fraction of the floor space when compared to other technologies.

ADVANTAGES OF FFSolution FH MACHINE

CONTACT US FOR MORE INFORMATION

TECHNICAL SPECIFICATIONS OF DPF CLEANING MACHINE

FH1 BASIC DOUBLE

Completely stainless steel

Cabin Size (cm) W-D-H without Electric Panel and Filtration Housing: 130-65-160

Size (cm) W-D-H with Electric Panel and Filtration Housing: 200-90-170

Weight: 400 kg

Tank: 180 liters

Water filtration: 10 Micron

Filters Volume: 11.00 m2

Drying temperature: approximately 50-55 Celsius

Water temperature: max 75 Celsius

Water heating: Yes

Printer: Yes

Touch screen: Yes

Backpressure reading: Yes

Flow reading: N/A

Water Pressure reading: N/A

Water recirculation pump: N/A

Volume washing pump: 160 l / min - at 50 Hz

Recirculation pump volume: N/A

Homogeneous temperature level: N/A

Automatic water filling: Yes

DPF cooling: No

Settable programs (3 Prog Washing - 3 Prog. Drying): Yes

Easy to use: Yes

Cleaning effectiveness: Yes

Components for DPF car cleaning: Yes

Automatic washing without turning the DPF (FFSolution patent): N/A

Automatic washing with STOP - START Function: Yes

Double function wash and dry two filters simultaneously: Yes

Shutdown and Automatic Switch-On Water Heating Element: Yes

Biodegradable washing solution: Yes

Trucks DPF not modular: Yes

Bus DPF (Modular): No

SCR (Modular): No

SCR: No

DOC : Yes

LDV: Yes

Car DPF: Yes

FH2 BASIC DOUBLE

Completely stainless steel

Cabin Size (cm) W-D-H without Electric Panel and Filtration Housing: 170-86-190

Size (cm) W-D-H with Electric Panel and Filtration Housing: 230-105-190

Weight: 650 kg

Tank: 280 liters

Water filtration: 10 Micron

Filters Volume: 11.00 m2

Drying temperature: approximately 50-55 Celsius

Water temperature: max 75 Celsius

Water heating: Yes

Printer: Yes

Touch screen: Yes

Backpressure reading: Yes

Flow reading: No

Water Pressure reading: No

Water recirculation pump: No

Volume washing pump: 160 l / min - at 50 Hz

Recirculation pump volume: No

Homogeneous temperature level: No

Automatic water filling: Yes

DPF cooling: No

Settable programs (3 Prog Washing - 3 Prog. Drying): Yes

Easy to use: Yes

Cleaning effectiveness: Yes

Components for DPF car cleaning: Yes

Automatic washing without turning the DPF (FFSolution patent): No

Automatic washing with STOP - START Function: Yes

Double function wash and dry two filters simultaneously: Yes

Shutdown and Automatic Switch-On Water Heating Element: Yes

Biodegradable washing solution: Yes

Trucks DPF not modular: Yes

Bus DPF (Modular): No

SCR (Modular): No

SCR: Yes

DOC : Yes

LDV: Yes

Car DPF: Yes

FH2 PRO DOUBLE

Completely stainless steel

Cabin Size (cm) W-D-H without Electric Panel and Filtration Housing: 170-86-190

Size (cm) W-D-H with Electric Panel and Filtration Housing: 230-105-190

Weight: 650 kg

Tank: 280 liters

Water filtration: 10 Micron

Filters Volume: 22.00 m2

Drying temperature: approximately 70-75 Celsius

Water temperature: max 75 Celsius

Water heating: Yes

Printer: Yes

Touch screen: Yes

Backpressure reading: Yes

Flow reading: No

Variable Backpressure measurament (50- 70 Hz) Drying Temp 70-75 C: Yes

Water Pressure reading: No

Water recirculation pump: 255 l / min - at 50 Hz

Volume washing pump: 160 l / min - at 50 Hz

Homogeneous temperature level: Yes

Homogeneous temperature level: Yes

Automatic water filling: Yes

DPF cooling: Yes

Settable programs (Washing - Drying): Yes

Easy to use: Yes

Cleaning effectiveness: Yes

Components for DPF car cleaning: Yes

Automatic washing without turning the DPF (FFSolution patent): N/A

Automatic washing with STOP - START Function: Yes

Double function wash and dry two filters simultaneously: Yes

Shutdown and Automatic Switch-On Water Heating Element: Yes

Biodegradable washing solution: Yes

Trucks DPF modular: Yes

Bus DPF (Modular): Yes

SCR (Modular): Yes

SCR: Yes

DOC : Yes

LDV: Yes

Car DPF: Yes

FH3 PRO DOUBLE

Completely stainless steel

Cabin Size(cm) W-D-H without Electric Panel and Filtration Housing: 200-90-190

Size (cm) W-D-H with Electric Panel and Filtration Housing: 270-105-190

Weight: 750 kg

Tank: 420 liters

Water filtration: 10 Micron

Filters Volume: 22.00 m2

Drying temperature: approximately 75-80 Celsius

Water temperature: max 75 Celsius

Water heating: Yes

Printer: Yes

Touch screen: Yes

Backpressure reading: Yes

Variable Backpressure measurament (50- 70 Hz) Drying Temp 70-75 C: Yes

Water Pressure reading: Yes

Water recirculation pump: Yes

Volume washing pump: Continuously 160 l / min - at 50 Hz

Recirculation pump volume: 255 l/min nominal

Homogeneous temperature level: Yes

Automatic water filling: Yes

DPF cooling: Yes

Settable programs (3 Prog Washing - 3 Prog. Drying): Yes

Easy to use: Yes

Cleaning effectiveness: Yes

Components for DPF car cleaning: Yes

Automatic washing without turning the DPF (FFSolution patent): Yes

Automatic washing with STOP - START Function: Yes

Double function wash and dry two filters simultaneously: Yes

Shutdown and Automatic Switch-On Water Heating Element: Yes

Biodegradable washing solution: Yes

Trucks DPF not modular: Yes

Bus DPF (Modular): Yes

SCR (Modular): Yes

SCR: Yes

DOC : Yes

LDV: Yes

Car DPF: Yes

The DPF Cleaning Machine is the safest, most efficient and cost effective DPF Cleaning System available to clean and salvage oil soaked diesel particulate filters.

The DPF Cleaning Machine is the perfect solution for those looking to enter the DPF cleaning market or those looking to increase their current capacity and capabilities with a more efficient and profitable solution.

Find out more about the DPF Cleaning System by contacting us at info@ffsolution.biz

The DPF Cleaning Machine is the perfect solution for those looking to enter the DPF cleaning market or those looking to increase their current capacity and capabilities with a more efficient and profitable solution.

Find out more about the DPF Cleaning System by contacting us at info@ffsolution.biz