What is DPF’s?

Legal Requirement? | DPF Warning Light? | DPF Regeneration?

LEGAL REQUIREMENTS AND THE MOT TEST

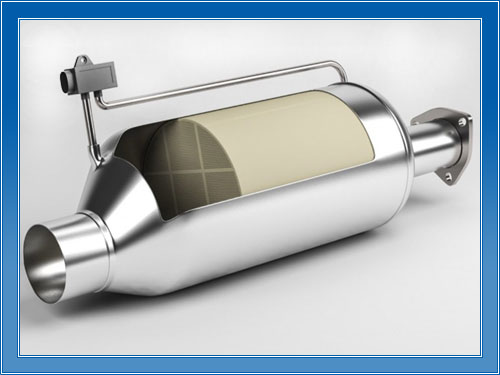

WHAT IS DPF'S ?

DOES MY VEHICLE HAVE A DPF FITTED?

DPF REGENERATION

Regeneration is the process of removing the accumulated soot from the filter. This is done either passively (from the engine’s exhaust heat in normal operation or by adding a catalyst to the filter) or actively introducing very high heat into the exhaust system. On-board active filter management can use a variety of strategies :

All on-board active systems use extra fuel, whether through burning to heat the DPF, or providing extra power to the DPF’s electrical system, although the use of a fuel borne catalyst reduces the energy required very significantly.

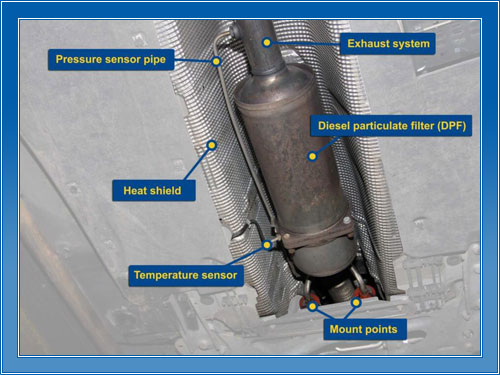

Typically a computer monitors one or more sensors that measure back pressure and/or temperature, and based on pre-programmed set points the computer makes decisions on when to activate the regeneration cycle. The additional fuel can be supplied by a metering pump. Running the cycle too often while keeping the back pressure in the exhaust system low will result in high fuel consumption. Not running the regeneration cycle soon enough increases the risk of engine damage and/or uncontrolled regeneration (thermal runaway) and possible DPF failure.

Diesel particulate matter burns when temperatures above 600 degrees Celsius are attained. This temperature can be reduced to somewhere in the range of 350 to 450 degrees Celsius by use of a fuel borne catalyst. The actual temperature of soot burn-out will depend on the chemistry employed. The start of combustion causes a further increase in temperature. In some cases, in the absence of a fuel borne catalyst, the combustion of the particulate matter can raise temperatures above the structural integrity threshold of the filter material, which can cause catastrophic failure of the substrate. Various strategies have been developed to limit this possibility. Note that unlike a spark-ignited engine, which typically has less than 0.5% oxygen in the exhaust gas stream before the emission control device(s), diesel engines have a very high ratio of oxygen available. While the amount of available oxygen makes fast regeneration of a filter possible, it also contributes to runaway regeneration problems.

Typically a computer monitors one or more sensors that measure back pressure and/or temperature, and based on pre-programmed set points the computer makes decisions on when to activate the regeneration cycle. The additional fuel can be supplied by a metering pump. Running the cycle too often while keeping the back pressure in the exhaust system low will result in high fuel consumption. Not running the regeneration cycle soon enough increases the risk of engine damage and/or uncontrolled regeneration (thermal runaway) and possible DPF failure.

Diesel particulate matter burns when temperatures above 600 degrees Celsius are attained. This temperature can be reduced to somewhere in the range of 350 to 450 degrees Celsius by use of a fuel borne catalyst. The actual temperature of soot burn-out will depend on the chemistry employed. The start of combustion causes a further increase in temperature. In some cases, in the absence of a fuel borne catalyst, the combustion of the particulate matter can raise temperatures above the structural integrity threshold of the filter material, which can cause catastrophic failure of the substrate. Various strategies have been developed to limit this possibility. Note that unlike a spark-ignited engine, which typically has less than 0.5% oxygen in the exhaust gas stream before the emission control device(s), diesel engines have a very high ratio of oxygen available. While the amount of available oxygen makes fast regeneration of a filter possible, it also contributes to runaway regeneration problems.

WHAT DOES THE DPF WARNING LIGHT MEAN?

PROBLEMS ENCOUNTERED WITH DPF

- If regeneration doesn’t function properly it leads to a build-up of soot affecting performance and fuel economy, left unattended this will result in a Blocked DPF which can ultimately cause very expensive damage to other engine components. A blocked DPF is also potentially dangerous as it can cause overheating in the exhaust system and cause a fire risk. To prevent this damage most new vehicles will go into “Limp Home” safety mode at this stage, meaning the vehicle will have minimum power barely sufficient to crawl home.

- For regeneration to take place it requires the vehicle to be driven regularly at some speed on open roads e.g. motorway driving, typically driving at around 2500 RPM for approx. 15-30mins at least once a month, this will keep things working.

- Many diesel vehicles are used primarily in urban areas or on short stop start journeys e.g. local deliveries, taxi’s, school runs etc and many have auto gearbox, so the vehicle does not get the chance to heat up sufficiently and is unable to carry out a full regeneration process.

- Even if the regeneration functions as it should, over time the Ash Residue will build up in the DPF and have the same affect ultimately resulting in a blocked DPF. For this reason a DPF is classified as a Serviceable Item by the vehicle manufacturers like brake pads or air filters etc and not covered under warranty. DPF systems therefore need to be maintained properly.

WHAT ELSE SHOULD I BE AWARE OF?

- It is often said that you should “go for a blast” down the motorway to clear the DPF. Please note this is only partially true. If the DPF is blocked beyond the capacity for regeneration or blocked due to Ash residue, you will do more harm to your engine.

- There are many DPF cleaning additives available promising a magic cure for DPF. We have yet to find one that will clear a blocked filter and will certainly not clear an Ash blocked filter. Some products can however be useful in keeping a functional DPF in good health.

- DPF units are closely linked with other emissions components, if these parts do not function properly they can help to block the DPF, similarly a blocked DPF can damage these components due to excess back pressure.

- DPF units are located close to the Turbo, if the turbo is leaking oil it can help to block the DPF, similarly a blocked DPF can damage the turbo due to excess back pressure.

- Some PSA engines fitted to Peugeot, Renault, Ford, Volvo and Nissan have an on board Fuel Additive System connected to the DPF to help regeneration. It is important to maintain this system and keep it topped up with the additive (only available from main dealers approx £130 per tank) if not it will block the DPF. In our experience this is often neglected, even by main dealers due to the cost. If you have the DPF removed this function as it is no longer required and can be disabled.

- Some vehicles have a dedicated DPF or Emissions or Anti-Pollution warning light which is great, however many will just have an Engine light on. It is important to check by diagnostics why the light is on and not advisable to simply get the light turned off without investigation.

- DPF work is complex and should only be carried out by experienced professionals with the correct specialist equipment. All work on a DPF has to be completed with the appropriate recalibration or reset on the vehicle ECU. It is not possible to simply delete the DPF electronically or just remove the DPF unit without work on the ECU.

- It is our experience that many garages including main dealers are not knowledgeable in DPF and related issues. Our dealers often see customers after they have spent a lot of money on the wrong fixes as the DPF fault was not correctly diagnosed.